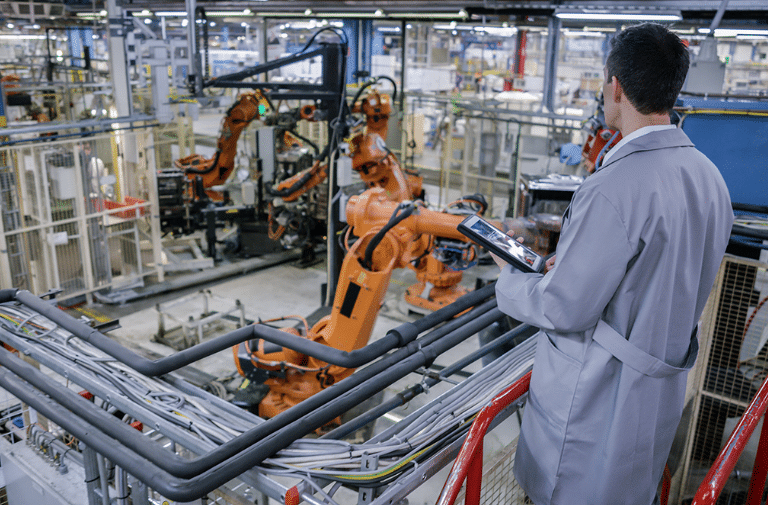

In today’s fast-paced business landscape, small manufacturing enterprises face the challenge of staying competitive and efficient while managing limited resources. The need for streamlined operations, data accuracy, and better decision-making processes has never been more critical. This is where Manufacturing ERP (Enterprise Resource Planning) software for small businesses comes into play. In this comprehensive guide, we will explore how Manufacturing ERP software empowers small businesses, enhances their operations, and helps them thrive in the highly competitive manufacturing sector.

Understanding Manufacturing ERP Software for Small Businesses

What is Manufacturing ERP Software?

Manufacturing ERP software is a powerful tool designed to assist small manufacturing businesses in managing and optimizing their core processes. It provides an integrated platform that enables companies to control and streamline various aspects of their operations, from production and inventory management to supply chain and financial management.

Why is Manufacturing ERP Software Vital for Small Businesses?

The challenges faced by small manufacturing businesses are unique, and traditional methods of operation often fall short. These businesses need to improve efficiency, reduce waste, enhance quality, and meet customer demands. Manufacturing ERP software is the answer to these challenges, as it allows businesses to:

- Streamline Operations: With Manufacturing ERP software, small businesses can automate and optimize their manufacturing processes, leading to reduced lead times and production costs.

- Improve Inventory Management: Accurate inventory tracking ensures that small manufacturers have the right materials in stock, reducing carrying costs and minimizing stockouts.

- Enhance Quality Control: ERP systems offer quality control features, ensuring that products meet stringent quality standards, reducing defects, and improving customer satisfaction.

- Boost Decision-Making: Manufacturing ERP software provides real-time data and analytics, enabling small businesses to make informed decisions promptly.

- Ensure Compliance: Small manufacturers often face industry-specific regulations. ERP software helps them stay compliant with these standards, reducing legal risks.

- Expand Scalability: As businesses grow, their needs change. ERP systems can scale with the company, ensuring that it continues to meet their evolving requirements.

Key Features of Manufacturing ERP Software for Small Businesses

Manufacturing ERP software for small businesses is a versatile tool that comes with various features tailored to meet the specific needs of the manufacturing sector. Let’s explore some of the key features that can transform small manufacturing operations.

1. Inventory Management

Efficient inventory management is crucial for small manufacturers. Manufacturing ERP software allows businesses to keep a close eye on inventory levels, track stock movements, and generate real-time reports on stock availability. This helps in minimizing excess inventory and stockouts, ensuring a smooth production process Inventory management is a critical aspect of any small manufacturing business. It involves overseeing the purchase, storage, and utilization of materials and products to ensure a smooth and cost-effective production process. Small manufacturers, in particular, can significantly benefit from efficient inventory management due to their limited resources. Let’s dive into the key components of effective inventory management for small businesses Maintaining an optimal level of inventory is essential. Overstocking ties up capital and storage space, while understocking can lead to production delays and customer dissatisfaction. Manufacturing ERP software for small businesses helps strike the right balance by providing real-time data on inventory levels and forecasting demand accurately.

2. Production Planning and Scheduling

Small manufacturers need to optimize their production processes to meet customer demand and reduce costs. ERP systems assist in creating production schedules, tracking work in progress, and making adjustments to ensure that production remains efficient and on schedule Holding costs include expenses related to storing inventory, such as rent, utilities, insurance, and labor. Small manufacturers need to minimize these costs to improve profitability. ERP systems assist in tracking inventory turnover rates and identifying slow-moving items, allowing businesses to make informed decisions about discontinuing or discounting products that are tying up resources, Running out of essential materials or products can lead to production stoppages and lost sales. Manufacturing ERP software helps small businesses avoid stockouts by setting up reorder points and triggering automatic orders when inventory levels drop below a specified threshold. This ensures a continuous flow of materials to support production.

3. Quality Control and Assurance

Quality is non-negotiable in manufacturing. ERP software enables small businesses to implement quality control measures, ensuring that products meet stringent quality standards. It also helps in identifying and addressing issues before they affect the final product Small manufacturers often rely on a limited number of suppliers. Maintaining strong supplier relationships is crucial for ensuring timely deliveries and competitive pricing. Manufacturing ERP software allows businesses to track supplier performance, negotiate better terms, and identify alternative suppliers to mitigate risks, JIT practices involve receiving materials just in time for production, reducing the need for extensive storage. Manufacturing ERP software supports JIT by providing visibility into demand forecasts, production schedules, and supplier lead times. This enables small businesses to time their orders precisely and minimize inventory holding costs.

4. Supply Chain Management

Effective supply chain management is essential for small manufacturers to ensure that they receive the right materials on time. Manufacturing ERP software allows businesses to monitor their suppliers, streamline procurement processes, and minimize supply chain disruptions Regularly auditing inventory is essential to maintain data accuracy and identify discrepancies. ERP systems facilitate cycle counting, which involves counting a subset of inventory items regularly, rather than performing a full inventory count. This reduces disruptions and ensures that discrepancies are identified and addressed promptly, Small manufacturers often produce goods in batches or lots. ERP software offers batch and lot tracking capabilities, allowing businesses to trace the production history of specific items. This is invaluable for quality control, compliance, and managing recalls in the event of product issues Accurate demand forecasting is crucial for small manufacturers. Manufacturing ERP software leverages historical data and market trends to create demand forecasts. This information is used to make informed decisions about inventory levels, production schedules, and material orders.

5. Financial Management

Small businesses can keep their finances in check with ERP software. It assists in managing expenses, tracking revenue, generating financial reports, and ensuring compliance with tax regulations Effective inventory management is closely linked to sales and production processes. Manufacturing ERP software provides real-time integration with these functions, ensuring that inventory levels are automatically adjusted as sales orders are received and production is scheduled. This eliminates manual data entry errors and reduces the risk of stockouts or overstocking. In conclusion, inventory management is a fundamental component of small manufacturing businesses, and Manufacturing ERP software is a powerful tool that can significantly enhance these operations. By optimizing stock levels, reducing holding costs, preventing stockouts, streamlining supplier relationships, implementing JIT practices, and leveraging advanced features like batch tracking and demand forecasting, small manufacturers can run more efficiently, reduce costs, and maintain a competitive edge in their industry.

6. Real-Time Analytics

Access to real-time data is a game-changer for small manufacturers. ERP software provides valuable insights through analytics and reporting, helping businesses make data-driven decisions, identify trends, and spot opportunities for improvement In today’s fast-paced business environment, the ability to access and interpret data in real-time has become a game-changer for small manufacturers. Real-time analytics, facilitated by Manufacturing ERP software, empowers these businesses to make informed decisions promptly, identify trends, and seize opportunities for improvement. Let’s explore the significance and benefits of real-time analytics for small manufacturing enterprises, Real-time analytics involves the continuous and immediate processing of data as it is generated. It provides small manufacturers with the ability to monitor and analyze critical operational data as it becomes available. This data can include information related to production, inventory, sales, quality control, and more.

7. Scalability

As small manufacturing businesses grow, their software needs to adapt. Manufacturing ERP software is highly scalable, allowing companies to add new features and users as required, ensuring that the system continues to support their growth allowing small manufacturers to respond swiftly to changing conditions or unexpected issues. This can be especially crucial in industries with volatile demand or rapidly changing market dynamics. By monitoring real-time data, small manufacturers can quickly identify bottlenecks, equipment failures, or quality control issues in their production processes. This immediate insight enables them to address problems as they arise, reducing production downtime and waste.

Implementing Manufacturing ERP Software

Selecting the Right Software

Choosing the right Manufacturing ERP software for your small business is a critical decision. It’s essential to assess your business’s specific needs, budget, and long-term goals. Look for software providers that offer solutions tailored to small manufacturing enterprises Real-time analytics helps in tracking inventory levels and sales in real time. This enables businesses to adjust orders, manage stock levels efficiently, and reduce carrying costs. It also helps in avoiding stockouts or overstocking, Quality issues can have a significant impact on small manufacturers. With real-time analytics, they can spot quality deviations as they occur and take corrective actions promptly. This results in improved product quality and customer satisfaction.

Training and Integration

Once you’ve selected the right ERP software, ensure that your employees are adequately trained to use it effectively. Integration with existing systems is also a crucial step in the implementation process. A well-executed integration ensures a smooth transition to the new system Real-time data allows small manufacturers to monitor sales trends, customer preferences, and order fulfillment in real time. This information is invaluable for making adjustments to marketing strategies, product offerings, and customer service, Real-time analytics can help small manufacturers predict production needs and adjust production schedules on the fly. This enables businesses to meet changing customer demands more effectively.

Data Migration and Testing

Migrating existing data to the ERP system can be complex. It’s essential to plan and execute data migration carefully to avoid data loss or errors. After migration, thorough testing is necessary to ensure that the system functions as expected By monitoring operational costs in real-time, small manufacturers can identify areas where cost savings can be achieved. This might include optimizing energy usage, labor allocation, or procurement decisions, In conclusion, real-time analytics is a powerful tool for small manufacturers, enabling them to make data-driven decisions and respond quickly to operational challenges. With the integration of Manufacturing ERP software, small businesses can access real-time data on production, inventory, quality, sales, and more. This capability is essential for maintaining a competitive edge in the dynamic world of manufacturing, where agility and responsiveness are key to success.

In the ever-evolving landscape of business technology, the need for efficient data management has become paramount. Data migration, the process of transferring data from one system to another, is a crucial aspect of this landscape. This article explores the intricacies of data migration and the equally significant aspect of data testing to ensure a seamless transition.

Planning for Data Migration

Before embarking on a data migration journey, it’s essential to have a comprehensive plan. Assessing the current state of data, setting clear objectives, and choosing the right migration method are key components. Without a well-thought-out plan, the risk of data loss and disruptions significantly increases.

Key Steps in Data Migration Process

The data migration process involves several key steps. Data extraction from the source system, transformation to fit the target system, loading into the new system, and thorough validation and verification are essential to maintain data integrity throughout the process.

Common Challenges in Data Migration

Despite meticulous planning, challenges are inevitable during data migration. Issues related to data quality, downtime, and security concerns may arise. Understanding and addressing these challenges proactively is crucial to the success of the migration process.

Importance of Data Testing

Data testing plays a pivotal role in ensuring the accuracy and reliability of migrated data. Testing at various stages, including unit testing, integration testing, and user acceptance testing, helps identify and rectify issues early in the process.

Types of Data Testing

Unit testing focuses on individual components, integration testing checks the interaction between different systems, and user acceptance testing ensures that the end-users can seamlessly work with the new system. A comprehensive testing strategy encompasses all these types to guarantee a robust migration.

Best Practices in Data Testing

Creating detailed test cases, conducting performance testing, and continuous monitoring are essential best practices in data testing. These practices not only identify potential issues but also contribute to the overall improvement of data management processes.

Tools for Data Migration and Testing

An array of tools facilitates data migration and testing. Understanding the features and suitability of popular tools is vital in making informed decisions for a smooth transition.

Case Studies

Examining both successful and unsuccessful data migration stories provides valuable insights. Learning from the experiences of others helps businesses avoid common pitfalls and adopt successful strategies.

Future Trends in Data Migration and Testing

The future of data migration and testing is influenced by emerging technologies. Automation, artificial intelligence, blockchain, and enhanced data security measures are expected to shape the landscape in the coming years.

Challenges in Implementing Manufacturing ERP Software

While Manufacturing ERP software offers a multitude of benefits, the implementation process can be challenging for small businesses. Some common challenges include AI-driven analytics will provide more accurate insights and predictive capabilities. Small manufacturers can anticipate trends, potential production issues, and demand fluctuations, allowing them to plan more effectively Machine learning algorithms can detect anomalies in production processes and quality control. This helps in identifying and addressing issues before they affect the final product AI can optimize production schedules based on real-time data, reducing downtime and improving efficiency, AI can assist in demand forecasting and inventory optimization, ensuring that small manufacturers maintain the right stock levels:

- Cost: Small businesses may face budget constraints when implementing ERP software. It’s crucial to carefully evaluate costs and benefits to ensure a positive ROI.

- Resistance to Change: Employees may resist the change, fearing complexity or job loss. Proper training and communication can help alleviate these concerns.

- Data Security: Small businesses must prioritize data security. Selecting a reputable ERP provider with robust security measures is essential.

- Customization: Tailoring the ERP system to meet specific business needs can be complex. Small businesses should work closely with the software provider to ensure customization aligns with their operations.

The Future of Small Manufacturing with ERP Software

Manufacturing ERP software continues to evolve, offering small businesses more advanced tools and capabilities. As technology advances, we can expect the following developments in the world of Manufacturing ERP software, Small manufacturing businesses are experiencing a significant transformation in the way they operate, and much of this transformation is being driven by the evolution of ERP (Enterprise Resource Planning) software. As technology continues to advance, the role of ERP software in small manufacturing is expected to undergo substantial changes. Here’s a glimpse into what the future holds for small manufacturers embracing ERP software. One of the most exciting developments in the world of small manufacturing is the integration of artificial intelligence (AI) and machine learning within ERP software. These technologies will play a pivotal role in enhancing decision-making, automating routine tasks, and providing deeper insights into operations. Here’s how AI and machine learning will impact small manufacturers:

- AI and Machine Learning Integration: AI-driven analytics and machine learning algorithms will provide more accurate insights and predictive capabilities.

- Cloud-Based Solutions: Cloud-based ERP solutions will become more prevalent, offering small manufacturers flexibility and scalability.

- IoT Integration: The Internet of Things (IoT) will play a more significant role in small manufacturing, allowing real-time monitoring of equipment and processes.

- Enhanced User Interfaces: User-friendly interfaces will make ERP software more accessible to employees at all levels of the organization.

- Mobile Accessibility: ERP systems will become more mobile-friendly, allowing business owners and employees to access critical data and make decisions on the go.

Conclusion

Manufacturing ERP software for small businesses is a game-changer in the world of manufacturing. It empowers small manufacturers to streamline operations, optimize production, improve quality, and make data-driven decisions. As the manufacturing sector becomes increasingly competitive, embracing ERP software is not just an option; it’s a necessity. Small businesses that invest in the right Manufacturing ERP software can expect to thrive, grow, and stay ahead of the competition in this dynamic industry. So, if you’re a small manufacturer looking to take your business to the next level, consider implementing Manufacturing ERP software, and watch your operations transform for the better.