In today’s fast-paced business environment, efficient production planning and inventory management are vital. Manufacturers and businesses worldwide rely on technology to streamline their operations. MRP software, short for Material Requirements Planning software, plays a pivotal role in this process. This article will delve into the world of MRP software, explaining what it is, its history, and how it benefits various industries.

Understanding MRP (Material Requirements Planning)

MRP stands for Material Requirements Planning, a methodology that helps businesses plan, organize, and manage their production processes. This approach involves calculating the materials needed for production, ensuring they are available at the right time, and optimizing the use of resources. MRP software automates these tasks, making them more efficient and accurate.

The Evolution of MRP Software

MRP software has come a long way since its inception in the 1960s. Initially, it was a basic system that focused on inventory control. Over the years, it has evolved into a comprehensive solution that integrates with other business processes, such as sales, procurement, and finance. The roots of MRP software can be traced back to the mid-20th century. In the early days, it primarily focused on inventory control. Manufacturers used it to monitor their stock levels, ensuring they didn’t run out of essential materials while avoiding overstocking, which tied up capital, The roots of MRP software can be traced back to the mid-20th century. In the early days, it primarily focused on inventory control. Manufacturers used it to monitor their stock levels, ensuring they didn’t run out of essential materials while avoiding overstocking, which tied up capital, With the advent of the digital age and the integration of computer technology into business processes, MRP software continued to evolve. It became an essential component of Enterprise Resource Planning (ERP) systems. The combination of MRP and ERP streamlined operations further, offering a holistic approach to managing resources, production, and business processes, Today’s MRP software has shifted to cloud-based and mobile solutions, making it more accessible and flexible for businesses. Cloud-based MRP allows real-time data access from anywhere, enabling businesses to adapt swiftly to market changes. It also offers scalability and cost-effectiveness.

Key Features of Modern MRP Software

Modern MRP software offers a range of features, including demand forecasting, production scheduling, inventory tracking, and order management. These features are designed to enhance production efficiency and reduce costs, making MRP software an indispensable tool for manufacturers, Modern MRP software incorporates advanced demand forecasting tools. By analyzing historical data and market trends, it helps businesses predict future demand for their products. This enables better planning and ensures that materials are ordered and production schedules are optimized based on anticipated demand, Efficient production scheduling is a cornerstone of modern MRP software. It allows businesses to create detailed production plans, ensuring that each order is completed on time. The software optimizes schedules to minimize downtime and resource wastage, ultimately increasing productivity, Real-time inventory tracking is crucial for avoiding overstocking and stockouts. Modern MRP software provides a comprehensive view of inventory levels, ensuring that materials are available when needed, reducing carrying costs, and minimizing the risk of stockouts.

Benefits of Implementing MRP Software

Implementing MRP software brings several advantages. It helps in reducing excess inventory, minimizing stockouts, and improving customer service. Furthermore, it enables businesses to respond quickly to changes in demand, thus enhancing their competitiveness, One of the most significant benefits of MRP software is the reduction of excess inventory. It ensures that materials are ordered and stocked precisely when needed, preventing overstocking and the associated carrying costs. This optimization leads to significant cost savings, MRP software’s ability to forecast demand and manage inventory ensures that businesses don’t run out of essential materials or components. This prevents costly stockouts and the potential loss of production time, helping maintain smooth operations, Accurate demand forecasting and timely order fulfillment are integral to customer satisfaction. MRP software ensures that customer orders are processed efficiently, leading to on-time deliveries and happier customers, By automating production scheduling and resource allocation, MRP software improves production efficiency. It minimizes downtime, optimizes machine and labor utilization, and reduces bottlenecks, ultimately increasing productivity.

Industries That Benefit from MRP Software

MRP software is not limited to a specific industry. It is used in manufacturing, retail, healthcare, and even service-oriented businesses. Its flexibility and adaptability make it suitable for any organization that needs to manage resources and materials efficiently,

- Discrete Manufacturing: MRP software is extensively used in industries that produce distinct items, such as automobiles, electronics, and machinery.

- Process Manufacturing: Industries like food processing, chemical manufacturing, and pharmaceuticals rely on MRP to manage complex production processes.

Choosing the Right MRP Software for Your Business

Selecting the right MRP software is a crucial decision. Factors to consider include the size of your business, industry-specific requirements, and scalability. Additionally, it’s essential to ensure the software integrates seamlessly with your existing systems.

Implementation Challenges and Solutions

While MRP software offers substantial benefits, its implementation can be challenging. Overcoming resistance to change and ensuring data accuracy are common issues. However, with proper planning and training, these challenges can be addressed, Implementing MRP (Material Requirements Planning) software can be a transformative step for a business, but it often comes with its set of challenges. Understanding and addressing these challenges is crucial for a successful implementation. Here are some common implementation challenges and their solutions:

How MRP Software Boosts Efficiency

One of the primary goals of MRP software is to improve efficiency. It achieves this by automating processes, reducing errors, and providing real-time insights. As a result, businesses can produce more with fewer resources, MRP software automates and optimizes production schedules, ensuring that each step of the manufacturing process is coordinated efficiently. This reduces downtime and delays, resulting in a more streamlined production process, Efficient allocation of resources, including labor, machinery, and materials, is a key aspect of MRP software. It helps businesses make the most of their available resources, minimizing waste and increasing productivity, Real-time inventory tracking and management are central to MRP software. It ensures that materials and components are available when needed and minimizes excess inventory. This reduces carrying costs and the risk of overstocking, MRP software can analyze historical data and market trends to predict future demand accurately. This enables businesses to plan production and procurement based on anticipated demand, eliminating unnecessary stockouts or overproduction.

Real-world Success Storie

To illustrate the impact of MRP software, we’ll explore a few real-world success stories. These examples will demonstrate how businesses have transformed their operations and achieved significant cost savings and efficiency improvements, To truly understand the impact of MRP (Material Requirements Planning) software on businesses, let’s explore a few real-world success stories. These examples demonstrate how organizations from various industries have harnessed the power of MRP software to transform their operations, achieve substantial cost savings, and boost efficiency. Toyota, a pioneer in lean manufacturing, adopted MRP software to enhance its production processes. By using MRP to manage their supply chain, Toyota streamlined their inventory, reduced waste, and improved production efficiency. This successful implementation played a significant role in making Toyota one of the world’s leading automotive manufacturers, Siemens, a global leader in the electronics industry, implemented MRP software to optimize their manufacturing processes. With MRP, they achieved precise materials planning, reduced production lead times, and improved resource utilization. This resulted in increased production capacity and improved competitiveness in the market.

Integrating MRP Software with ERP

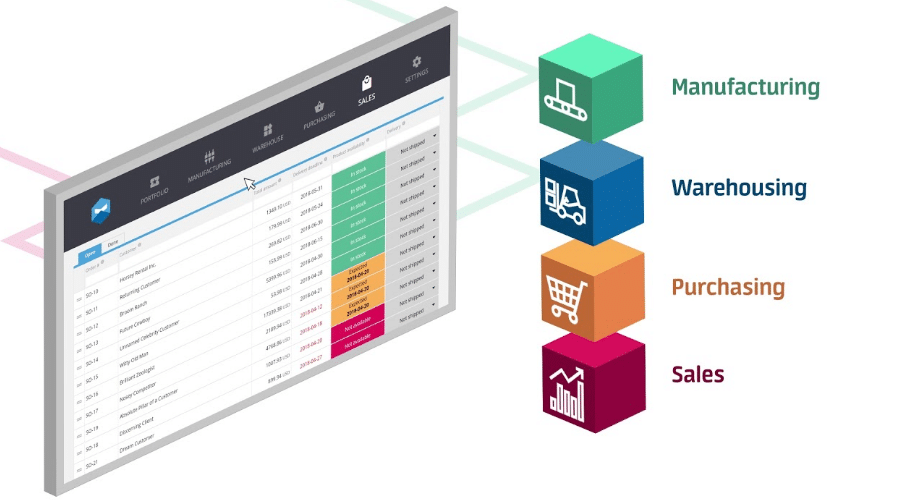

Many businesses choose to integrate MRP software with their Enterprise Resource Planning (ERP) systems. This integration provides a comprehensive view of business processes, from production and procurement to finance and human resources, The integration of MRP (Material Requirements Planning) software with ERP (Enterprise Resource Planning) systems is a strategic move that many businesses are making to streamline their operations and gain a comprehensive view of their organization. This integration enhances efficiency, reduces data silos, and improves decision-making. Here’s a closer look at the process of integrating MRP software with ERP. MRP and ERP systems serve different but complementary purposes. MRP focuses on materials and production planning, while ERP covers a broader spectrum of business functions, including finance, human resources, and customer relationship management. The integration aims to combine these functions seamlessly to improve overall operations, Integrating MRP with ERP starts with data integration. Data from MRP, such as production schedules, inventory levels, and materials requirements, needs to flow into the ERP system. This ensures that every department has access to the latest data for planning and decision-making, One of the significant benefits of integration is the ability to provide real-time updates. As MRP software updates with changes in materials and production requirements, these changes can be immediately reflected in the ERP system. This means that the finance department can see how changes in production schedules impact budgets, and HR can adjust workforce planning accordingly.

MRP Software and Inventory Management

Efficient inventory management is a key component of MRP software. It helps businesses optimize their stock levels, reduce carrying costs, and ensure materials are available when needed, Inventory management is a critical aspect of business operations, and MRP (Material Requirements Planning) software plays a pivotal role in this arena. By effectively managing materials and resources, MRP software significantly influences how businesses handle inventory. Here’s a detailed look at the relationship between MRP software and inventory management, One of the core functions of MRP software is demand forecasting. It uses historical data and market trends to predict future demand accurately. This feature directly impacts inventory management by ensuring that businesses stock the right quantity of materials. Underestimating demand can lead to stockouts, while overestimating can result in excess inventory. MRP software helps strike the perfect balance. MRP software enables businesses to implement the just-in-time (JIT) inventory approach. This means materials are ordered and received just in time for production, minimizing the need for extensive warehousing. JIT inventory reduces carrying costs, improves cash flow, and minimizes the risk of obsolete inventory.

The Future of MRP Software

As technology continues to advance, MRP software will also evolve. The future may bring even more automation, enhanced data analytics, and improved integration with other software solutions, MRP (Material Requirements Planning) software has come a long way since its inception in the 1960s. As technology continues to advance and businesses evolve, the future of MRP software holds exciting possibilities. Here are some key trends and developments to look forward to. The future of MRP software lies in its ability to harness the power of data analytics. By collecting and analyzing vast amounts of data, MRP software will provide predictive insights and actionable recommendations. This will enable businesses to make informed decisions, optimize their processes, and stay ahead of market changes.Automation is a significant driver of efficiency, and MRP software will continue to incorporate AI and machine learning to further reduce manual interventions. For instance, AI algorithms can optimize production schedules in real-time, allocate resources efficiently, and adapt to changing demand patterns.

MRP Software Pricing Models

Pricing for MRP software varies based on factors like the number of users, features, and support. Understanding the pricing models is essential for businesses looking to implement MRP software. When considering the implementation of MRP (Material Requirements Planning) software, understanding the pricing models is essential for businesses looking to make the right choice based on their needs and budget. MRP software pricing can vary based on several factors. Here are some common pricing models: In this model, the cost of MRP software is determined by the number of users who will be using the software. Each user is typically required to have a license. This pricing model is straightforward and easy to understand. Some MRP software providers offer modular pricing. Businesses can choose specific modules or features they need, and they are charged accordingly. This provides flexibility, allowing companies to pay only for the functionality they require.